How to build push/pull rotary switches.

Quite some time no update on the website, but that doesn’t mean, nothing got done 🙂

I finished my take on the push/pull-to-rotate function on the some knobs, like on the AVIONICS PWR panel.

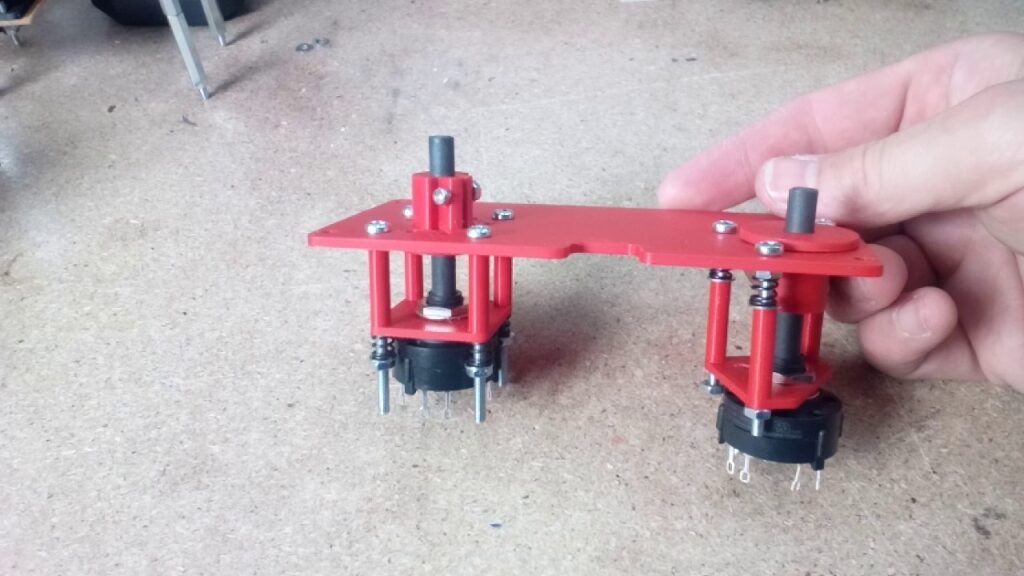

Some rotary switches in the F-16 require a push or pull to be able to rotate the switch into or out of a specific position.

Of course such switches can be bought, but I think you can imagine the price of those, so I decide to build them on my own.

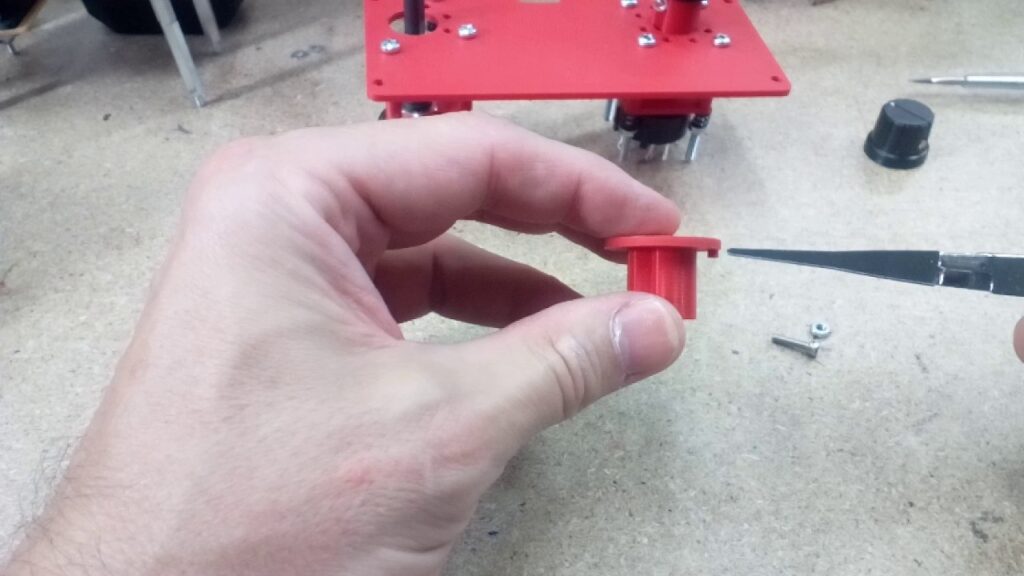

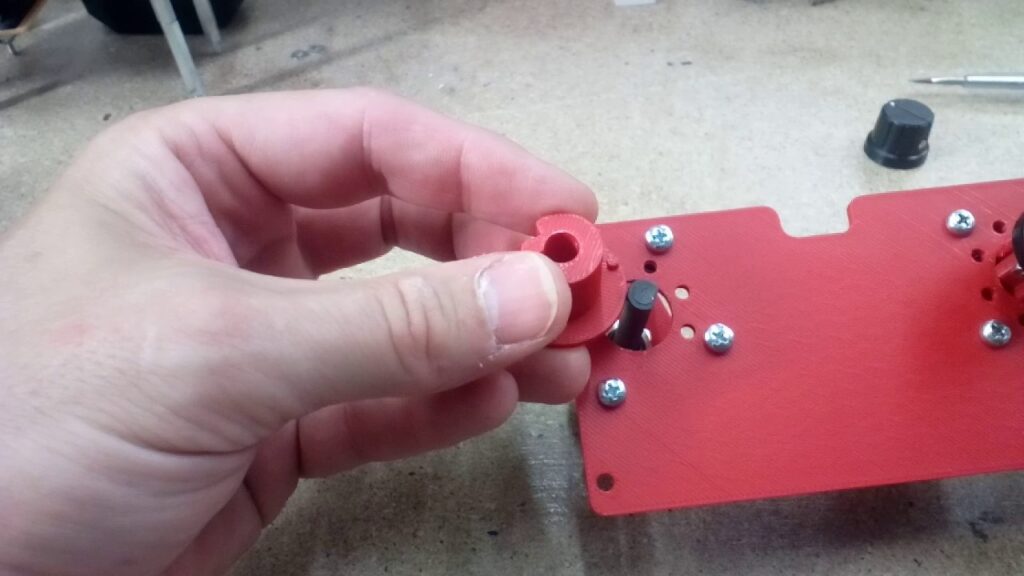

A locking disc with a slotted hole to clamp it to the rotary shaft has a little knob that fits into one or more positions on the mounting plate.

The switch itself is mounted on a sliding mechanism held by 4 (or 3, since there is very little room on the side of the panel) screws.

I included such “switch plates” for every panel, so only a hole for the shaft is needed in the backplate. This will make it possible to mount SMD LEDs directly under the knobs for backlighting.

So I also designed and printed some shaft extenders, same clamping mechanism using a 2.5mm nut and bolt – all tests show, that it’s easily strong enough.

Here’s a little video about how I make those switches.