The consoles are going to be reworked.

A few months ago my plan for the sim was to make it flyable as soon as possible.

But after having a look at DCS and recognizing how many things in BMS are now functional compared to the last time it was operational, I decided to to a big makeover of all consoles.

When I started my journey, only few infos about the cockpit were available – so it’s no wonder, that quite a lot of my measurements were wrong.

For example all my panels are 140mm in width, whereas in reality they are exactly 146.05mm. But more important are the heights of my panels which are off a lot compared to the correct dimensions.

Also I used a lot of small 6mm mini-toggle switches and those just don’t feel right anymore, since for some of my “newer” panels I went with the correct 12mm switches.

With DCS and BMS both having more current panels in it, it is time to rework my old panels and finally add the missing ones I didn’t have done yet (TEST, KY58…).

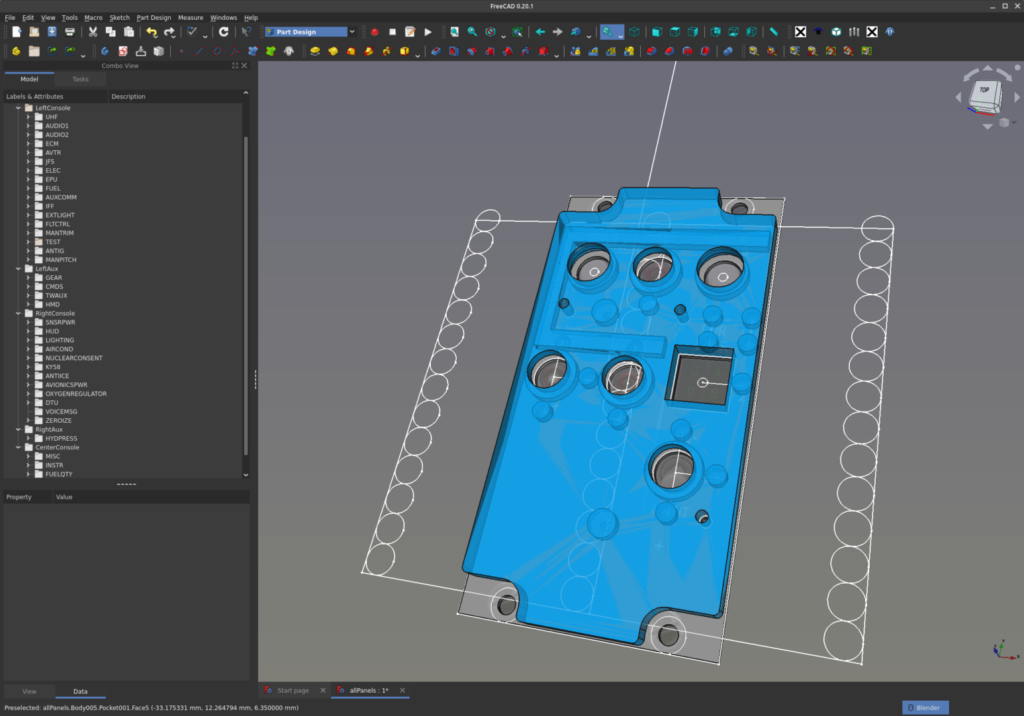

This time I’m going “all-in” and make all panels backlit with an 1.5 aluminium backplate and a 6.35mm high lightplate. Lettering will be done by spraypainting the lightplate and lasering away the black paint and all the panels will have the correct width and heights. Here’s how the TEST panel looks in FreeCAD.

And that’s the reason why I have to rework my consoles. The old tops are completely made out of cheap wood and to make it hold the panels I really had to sacrifice space.

Here’s the left console (which I started with) as it looks at the moment.

As you can see, with the new panels being correct in dimensions they wouldn’t fit anymore into the holes in the top.

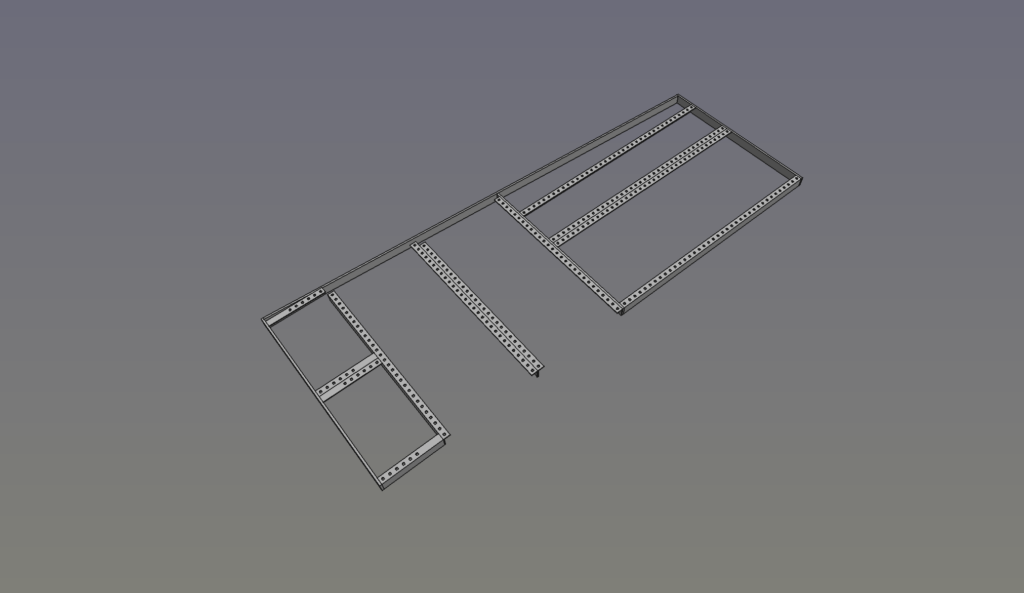

I decided to leave the main structures as they are and just make new consoles, this time I’m going to weld them from 10x20mm steel angle brackets and 3x15mm flat steel.

The basic design in FreeCAD has already been done (flat steel at the side still missing and ignore the wrong hole pattern at the back *gg*).

If everything works out as intended the new console will hopefully fit exactly into the wooden structure.

I already started making the “fake” Dzus rails to mount the panels to. Instead of drilling and tapping all the holes (not all are used by the panels) I just center drilled all and just have to finish and tap the ones needed for the specific panel. If I ever will have the need for other panel holes I can easily drill and tap them when needed.

With the DRO on my milling maching, spacing all the holes the exact 9.525mm from each other was quite easy 🙂

Two of the front three rails are done center drilling, one left to go.

I’m really excited about the new consoles and hopefully the left top will be finished soon!