The instruments for the hydraulic pressure are nearly done.

I didn’t have much time for building the last weeks but I managed to do some instruments in CAD.

When building them I started with the HYD PRESS gauges.

Because of the small diameter (1″) and the much bigger size of the servos I couldn’t do it the same way I built the VVI or AOA gauge with everything inside one housing..

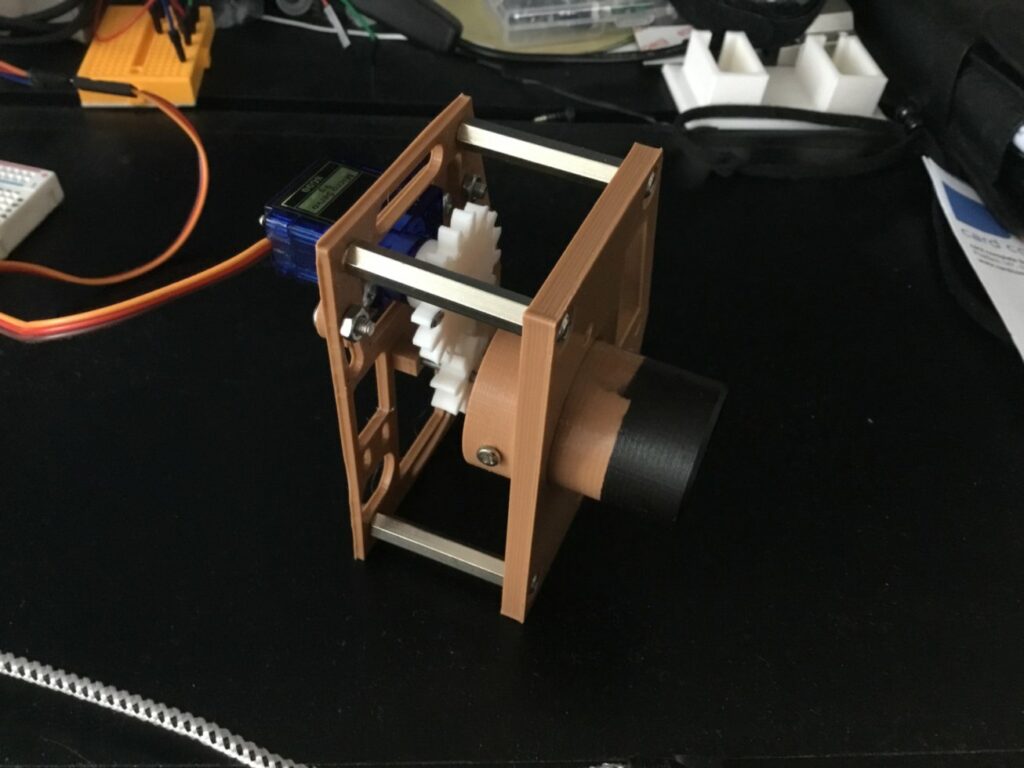

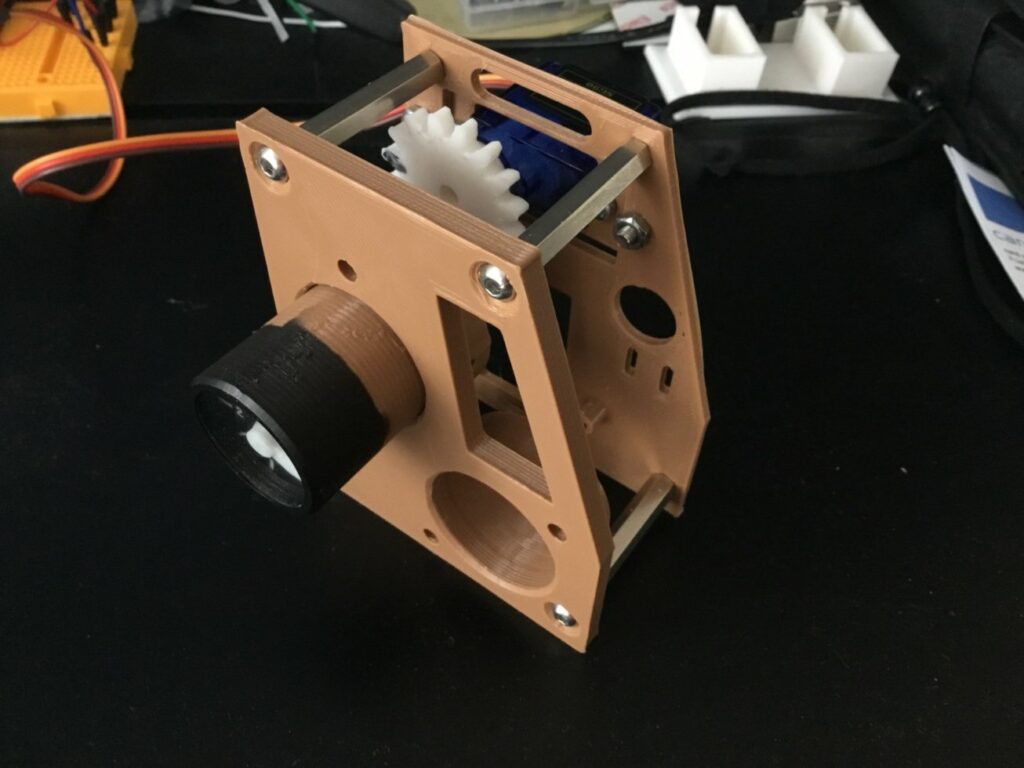

So I designed a construction where all seros and gauges will be mounted and then this construction will be screwed to the RightAux console using the holes regularily used for the small gaugeholders.

On the left ist the mainplate, next the servoplate and a servo with holderplate and gears.

A 1:2 gear ratio is used to get the needed angle for the servos.

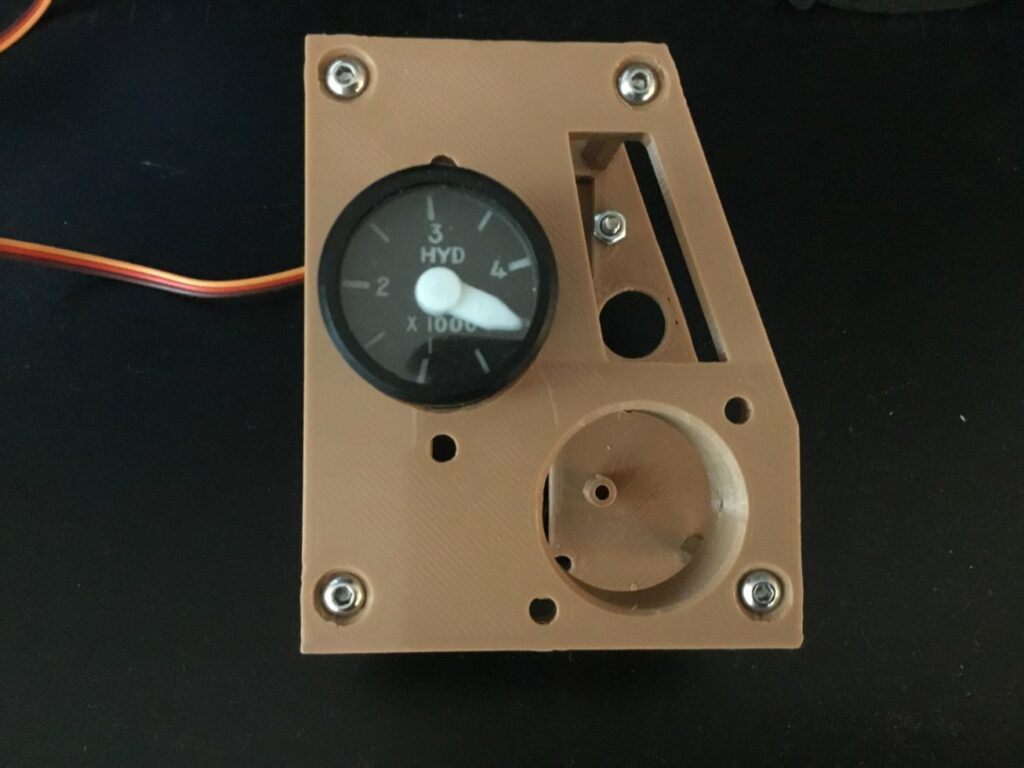

The gauges themselves are build quite easily:

- The outer hull with a lip on the front, in which all other parts are inserted from behind.

- At first the glass

- the the small front spacer

- needle and shaft

- faceplate

- and finally the back spacer

To keep the faceplate aligned I added a small nose to the hullfront and a notch to the faceplate.

The backspacer got 4 additional 5mm holes for the backlighting LEDs

Looks quite nice when put together.

Backlighting also works perfectly!

The first movement Test of the needle looks quite promising.

I screwed up the second faceplate when lasering (wrong positioning) and will have to do it again.

But more or less the HYD PRESS gauges could be seen as DONE 🙂