All parts for the right console are done.

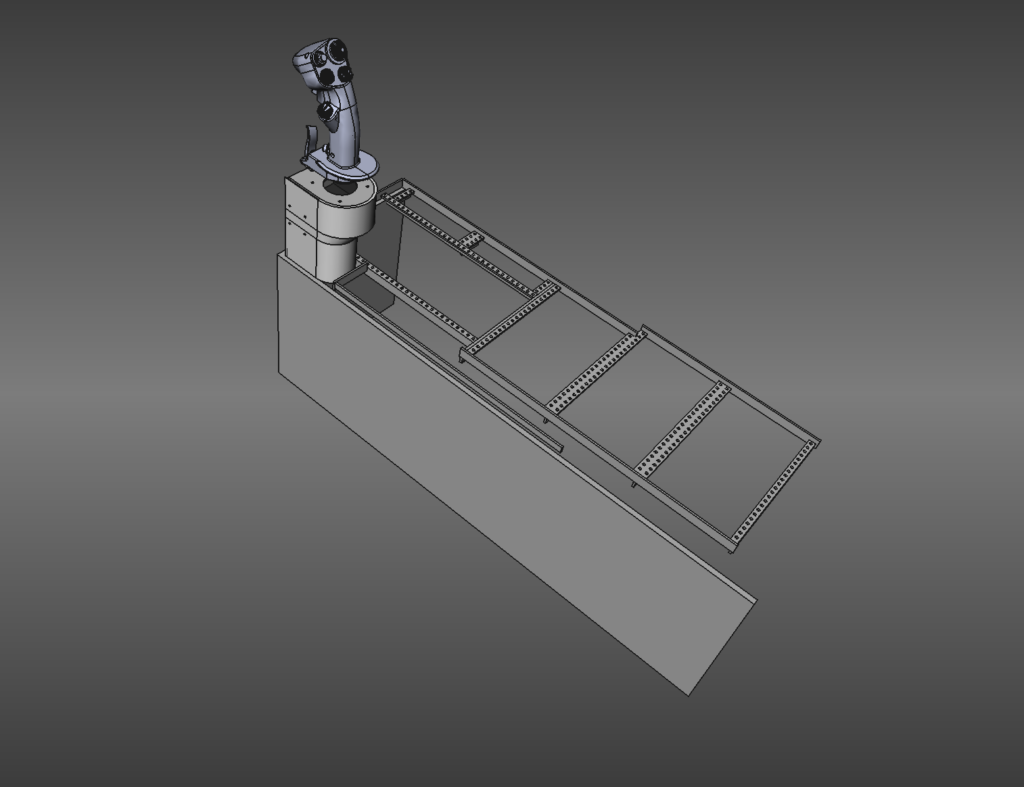

As usual the whole right console has been designed in FreeCAD.

This way I could get all the necessary dimensions and could start at the milling machine.

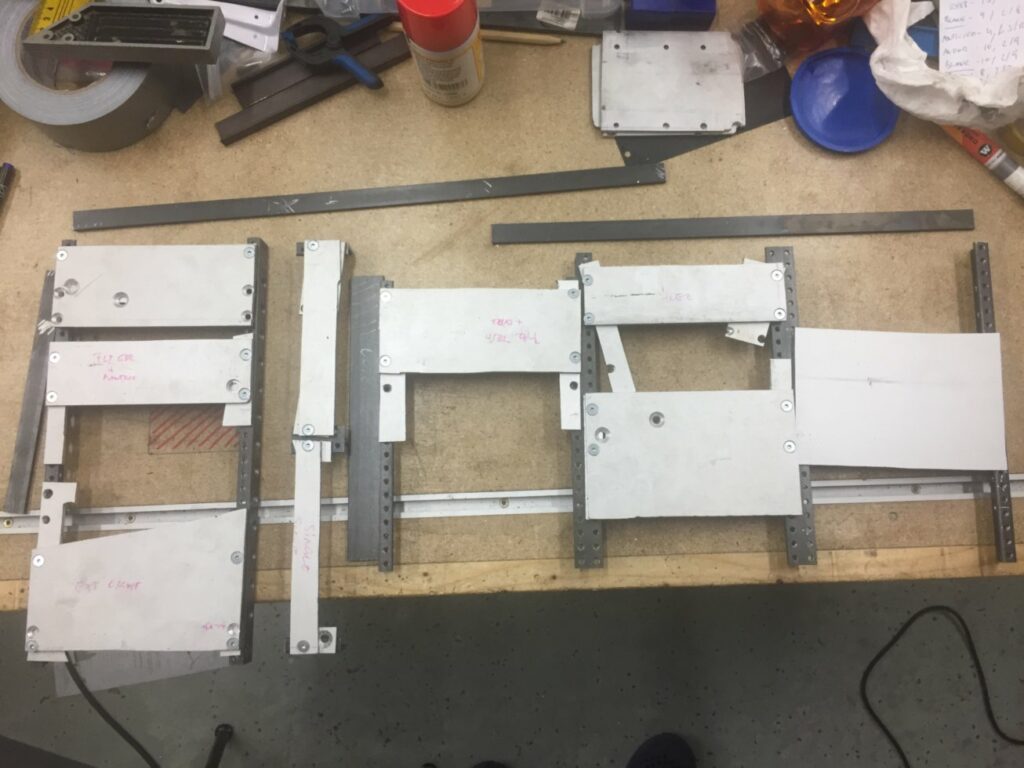

Those are the resulting parts (from left):

– frontpanelmount (SNSPWR, HUD, LIGHTING, AIRCOND)

– narrow panelmount above the frontpanes (NUC)

– all 3 other panelmounts together

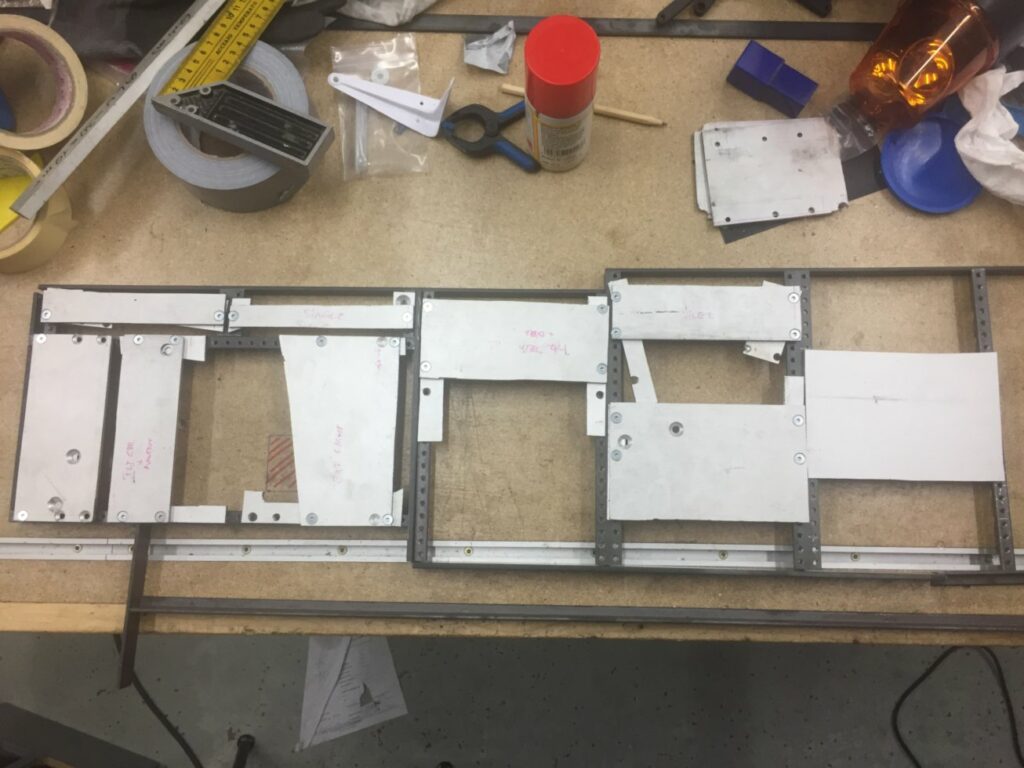

Finally (nearly) all parts put together for the pic.

All the framing parts will be cut to length after welding the panelmounts, so the distances are perfect.

Welding the console has been a lot easier than the left side, everything is straight and right angles.

Quite a lot of aluminium parts used as distance holders can be used otherwise now 🙂

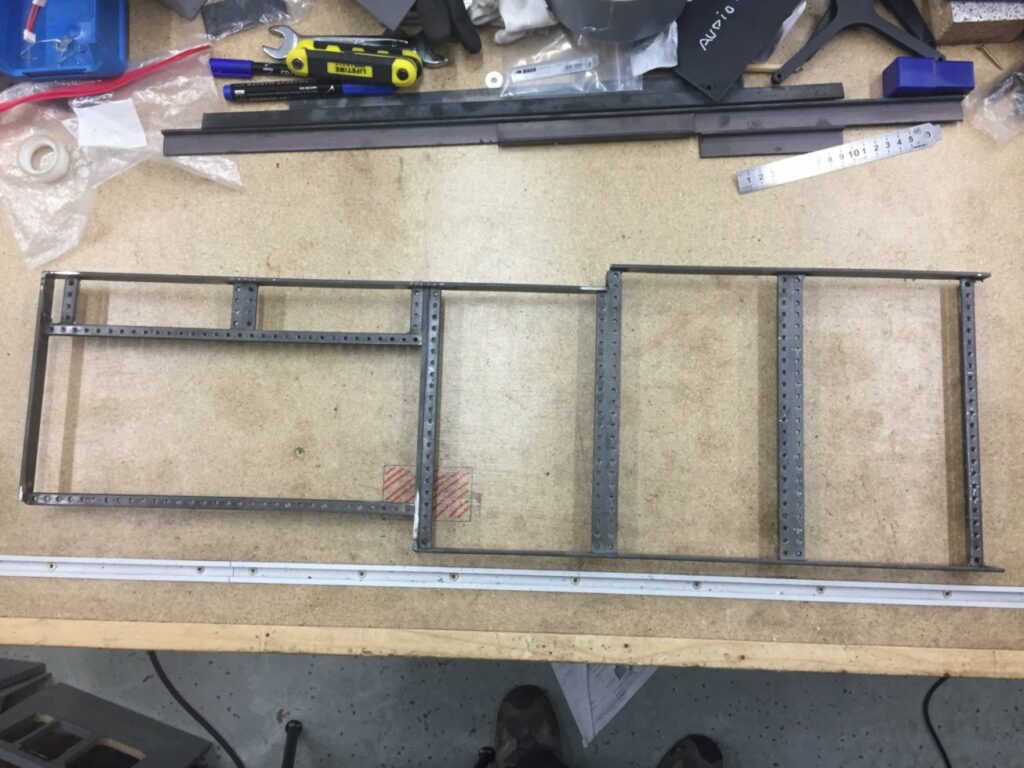

I 3D-printed some of parts for the FCC mount, put them together with some tape and clamped it to the mainframe.

Looks very ok to me 🙂

I guess I will put a small wedge between the front of the mainframe and the mount to get a little backwards angle like the real SCC.

Of course I had to fit the console to the mainframe 🙂

I had planned to build the inside part also, but now I’m thinking about just fill it with 3D printed parts.